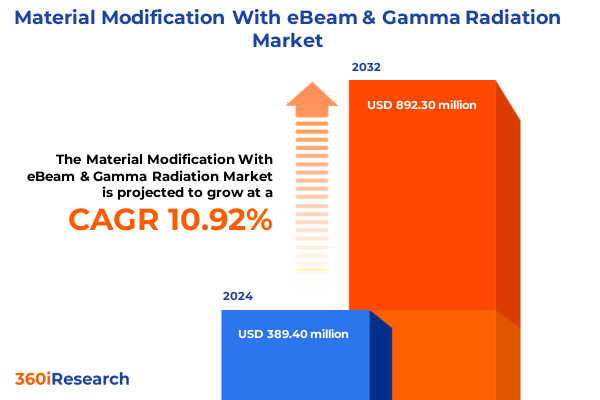

The Material Modification With eBeam & Gamma Radiation Market size was estimated at USD 430.67 million in 2025 and expected to reach USD 476.97 million in 2026, at a CAGR of 10.96% to reach USD 892.30 million by 2032.

Establishing the Foundation for Advanced Material Modification: An Overview of Emerging Applications and Innovations in Electron Beam and Gamma Radiation Processing

As industries navigate an era defined by rapid innovation and heightened material performance demands, the integration of accelerated radiation technologies is reshaping possibilities across manufacturing, healthcare, and consumer goods. Electron beam and gamma radiation techniques stand at the forefront of material modification, offering unmatched precision in crosslinking polymers, sterilizing critical medical devices, and imparting advanced surface properties. This introductory overview frames the core principles and current state of these transformative approaches, providing a foundational understanding for decision-makers seeking to harness their full potential.

Emerging applications underscore the strategic importance of high-energy processing methods in enhancing product reliability and accelerating time to market. From bolstering the thermal stability of automotive under-the-hood components to ensuring sterility for pharmaceutical packaging, the versatility of eBeam and gamma irradiation processes is driving cross-industry adoption. By delineating the basic mechanisms-where electrons or high-energy photons interact with polymer chains or microbial contaminants-this section sets the stage for a deeper exploration of how irradiation parameters can be optimized to achieve desired outcomes.

By tracing the evolution from early research prototypes to fully integrated industrial systems, the introduction also highlights critical enablers such as advancements in accelerator design, real-time dosimetry controls, and regulatory harmonization efforts. This synthesis equips stakeholders with the context needed to appreciate subsequent analyses on market dynamics, segmentation insights, and actionable guidance for leveraging these technologies in competitive environments.

How Technological Innovations and Sustainability Drives Have Transformed the Material Modification Ecosystem Using High-Energy Radiation

Over the past decade, the landscape of material modification via irradiation has undergone seismic shifts influenced by technological breakthroughs and shifting end-user requirements. Innovations in electron accelerator efficiency and cobalt-60 source management have reduced operational costs while expanding processing throughput capacities. This transformation is further propelled by the convergence of digital controls that enable real-time monitoring of dose distribution, ensuring consistent quality across high-volume production runs.

Simultaneously, sustainability imperatives are steering industry adoption. Companies are increasingly attracted to irradiation methods that eliminate chemical residues and minimize water usage, aligning with global environmental regulations and corporate responsibility targets. The reduction of reliance on traditional thermal or chemical crosslinking agents underscores a broader shift toward cleaner, more resource-efficient production pathways.

Strategic partnerships between equipment manufacturers, research institutions, and end users have accelerated knowledge transfer and driven the refinement of protocols for diverse substrates. Whether optimizing eBeam parameters for ultra-thin medical film sterilization or calibrating gamma radiation exposure for food safety, these collaborative ventures underscore a movement away from one-size-fits-all solutions to tailored process configurations. As a result, businesses are now able to deploy modular, scalable irradiation systems that address specific quality benchmarks without sacrificing operational flexibility.

Examining the Ripple Effects of 2025 Tariff Adjustments on Supply Chain Resilience and Cost Structures in Radiation Processing

The imposition of revised tariff structures in early 2025 has introduced new complexities into the supply chains underpinning irradiation processing equipment and source materials. Import duties on imported cobalt-60 sources and specialized electron accelerator components have prompted manufacturers to reassess procurement strategies. In response, several solution providers have localized certain assembly operations to mitigate cost fluctuations and maintain pricing stability for end users.

These tariff-induced adjustments have a cascading effect on total landed cost models, particularly for small and medium-sized enterprises with limited negotiating leverage. By compelling a rethink of supplier diversification, they have accelerated the move toward domestic sourcing of key consumables and spare parts. This has proven advantageous in regions where infrastructure investments already support radiation processing, fostering closer collaboration between local suppliers and system integrators.

Moreover, the evolving tariff environment is spurring a reevaluation of long-term capital expenditure plans. Organizations are now factoring in duty-related risk premiums when projecting payback periods for irradiation installations. In certain cases, leasing models for accelerator equipment have gained traction as a mechanism to circumvent upfront tariff burdens, spreading financial exposure over time and preserving working capital for other innovation-focused initiatives.

Unpacking the Complex Layers of Application, Process, and End-Use Dynamics Shaping Radiation-Based Material Modification

In exploring market segmentation by process type, it is evident that crosslinking applications dominate discussions around polymer enhancements, with dedicated eBeam crosslinking and gamma crosslinking pathways each offering distinct advantages in terms of penetration depth and throughput. Sterilization processes span eBeam sterilization, gamma sterilization, and X-ray sterilization options, where the choice among them is guided by product geometry and regulatory requirements. Meanwhile, surface modification via eBeam and gamma treatments is emerging as a pivotal tool for tailoring surface energy and adhesion properties in advanced electronics and biomedical implants.

When viewed through the lens of technology type, electron beam solutions bifurcate into high energy and low energy systems tailored for throughput and precision respectively. High-energy accelerators are well suited for bulk material crosslinking, whereas low-energy units deliver fine-tuned surface treatments with minimal substrate degradation. Correspondingly, gamma radiation offerings are distinguished by isotope selection, whether cobalt-60 for established industrial reliability or cesium-137 for specialized laboratory and pilot-scale deployments.

Diving into application-oriented segmentation, device sterilization remains a critical use case driven by stringent healthcare standards, while electronics surface treatment is growing rapidly in response to miniaturization trends. Food irradiation is gaining acceptance as regulatory landscapes adapt, and polymer crosslinking for films, tubing, and wire & cable continues to underpin high-performance material requirements. Dose range segmentation further refines process design, with high-dose operations exceeding 50 kGy suited for rigorous crosslinking, medium-dose applications in the 10-50 kGy band balancing sterilization with polymer integrity, and low-dose treatments below 10 kGy addressing surface and shelf-life use cases.

End-use industry perspectives reveal a diverse ecosystem where automotive electrical systems and under-the-hood components leverage material durability gains, printed circuit boards and semiconductors benefit from advanced surface finishes, dairy and beverage packaging exploits sterilization for product longevity, medical devices and pharmaceuticals depend on aseptic assurance, and paper and plastic packaging segments seek cost-effective, residue-free barrier enhancements.

This comprehensive research report categorizes the Material Modification With eBeam & Gamma Radiation market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Offering

- Process Type

- Technology Type

- Dose Range

- Application

- End-Use Industry

Exploring Regional Drivers and Strategic Investments That Define the Future of Irradiation Processing in Key Global Markets

Across the Americas, investment in irradiation infrastructure has accelerated, driven by robust healthcare and packaging sectors demanding scalable sterilization and crosslinking services. Regional customization efforts are evident, with Latin American markets adapting gamma radiation processes to local agricultural export requirements, while North American players focus on high-throughput eBeam crosslinking for automotive and electronics manufacturing clusters.

Within Europe, Middle East & Africa, stringent regulatory harmonization across the European Union has underpinned widespread adoption of irradiation technologies. Concurrently, the Middle East is emerging as a strategic hub for cobalt-60 processing facilities due to favorable energy economics and geostrategic positioning. In Africa, pilot programs are testing gamma irradiation for phytosanitary applications to bolster food export capabilities.

Asia-Pacific continues to lead in capacity expansions, with China and India investing heavily in electron accelerator installations to support domestic pharmaceutical and packaging industries. Southeast Asian nations are leveraging irradiation services to meet growing seafood export sterilization standards, and advanced research centers in Japan and South Korea are pioneering next-generation hybrid irradiation systems that combine eBeam and gamma sources for tailored processing.

This comprehensive research report examines key regions that drive the evolution of the Material Modification With eBeam & Gamma Radiation market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting How Industry Leaders Are Driving Innovation Through Modular Platforms, AI-Enabled Controls, and Strategic Partnerships

Leading equipment manufacturers are distinguishing themselves through investments in modular accelerator platforms that allow rapid configuration changes between crosslinking and sterilization modes, effectively meeting diverse client requirements without costly downtime. Select technology providers are integrating AI-driven dosimetry analytics to enable predictive maintenance and continuous process verification, thereby elevating operational uptime and ensuring compliance with evolving quality standards.

Irradiation service providers are forging partnerships with end-user verticals, embedding mobile gamma facilities within pharmaceutical manufacturing sites to streamline validation and reduce logistical complexities. Collaboration between equipment OEMs and consumable suppliers has given rise to optimized dose delivery capsules that minimize source decay impacts and extend maintenance cycles, enhancing overall system cost-effectiveness.

Meanwhile, specialized solution integrators are carving out niches in high-margin segments such as semiconductor surface treatment and medical-grade polymer crosslinking. These players leverage proprietary coatings and irradiation parameter sets to deliver differentiated performance characteristics, establishing themselves as preferred partners for OEMs seeking competitive advantages in product lifespan and reliability.

This comprehensive research report delivers an in-depth overview of the principal market players in the Material Modification With eBeam & Gamma Radiation market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Best Theratronics Ltd.

- BGS Beta-Gamma-Service GmbH & Co. KG

- CGN Dasheng Electron Accelerator Co., Ltd.

- E-BEAM Services, Inc.

- Eagle Medical, Inc.

- General Electric Company

- GREENPIA TECHNOLOGY

- IBA Industrial, Inc.

- Ionisos SAS

- Mitsubishi Electric Corporation

- NextBeam LLC

- Nissin Ion Equipment Co., Ltd.

- ScandiNova Systems AB

- Scapa Healthcare by Mativ Holdings, Inc.

- Steri-Tek, Inc.

- Sterigenics International, LLC by Sotera Health Company

- STERIS plc

- Symec Engineers Ltd.

- Vanform Corporation

- WASIK Associates, Inc.

Empowering Strategic Adaptability and Operational Excellence Through In-House Validation and Collaborative Standardization Efforts

To harness the full spectrum of benefits offered by electron beam and gamma radiation technologies, industry leaders should prioritize the development of flexible processing frameworks that can adapt to shifting application requirements. Establishing in-house irradiation capability for pilot-scale validation will position organizations to iterate rapidly on material formulations and process parameters before committing to large-scale deployments.

Investments in advanced data analytics and real-time dosimetry monitoring are recommended to optimize energy consumption and yield consistent quality outcomes. By leveraging AI-powered predictive maintenance, businesses can preempt equipment downtime, manage source decay proactively, and minimize disruptions to critical production schedules.

Forming collaborative consortiums with regulatory bodies, equipment vendors, and end-user representatives will accelerate the establishment of harmonized standards, reducing barriers to market entry across jurisdictions. Furthermore, exploring alternative financing models-such as equipment-as-a-service-can alleviate upfront capital constraints, enabling mid-tier enterprises to benefit from high-end irradiation capabilities without prohibitive investment thresholds.

Detailing a Multi-Faceted Research Framework That Blends Qualitative Interviews, Quantitative Benchmarking, and Regulatory Analysis

This analysis integrates qualitative insights from expert interviews with industry engineers, regulatory advisors, and R&D specialists, supplemented by a review of technical white papers and published standards. Data triangulation was achieved by cross-examining device case studies, vendor technical specifications, and peer-reviewed academic research to ensure consistency and reliability of findings.

Process performance metrics, including dose uniformity, throughput efficiency, and maintenance intervals, were validated through proprietary benchmarking protocols. Primary data from installation reports and service logs provided empirical grounding for discussions around operational uptime and total cost-of-ownership factors. Additionally, secondary research encompassed regulatory frameworks from leading market jurisdictions, aligning technical considerations with compliance imperatives.

The segmentation insights derive from a systematic categorization of process types, technology variants, application domains, dose thresholds, and end-user industries, informed by both historical adoption patterns and emerging use-case developments. Regional and company-level analyses leverage public disclosures, strategic partnership announcements, and equipment deployment records to render a comprehensive view of current market dynamics.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Material Modification With eBeam & Gamma Radiation market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Material Modification With eBeam & Gamma Radiation Market, by Offering

- Material Modification With eBeam & Gamma Radiation Market, by Process Type

- Material Modification With eBeam & Gamma Radiation Market, by Technology Type

- Material Modification With eBeam & Gamma Radiation Market, by Dose Range

- Material Modification With eBeam & Gamma Radiation Market, by Application

- Material Modification With eBeam & Gamma Radiation Market, by End-Use Industry

- Material Modification With eBeam & Gamma Radiation Market, by Region

- Material Modification With eBeam & Gamma Radiation Market, by Group

- Material Modification With eBeam & Gamma Radiation Market, by Country

- United States Material Modification With eBeam & Gamma Radiation Market

- China Material Modification With eBeam & Gamma Radiation Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 2703 ]

Synthesizing Technological Trends and Regulatory Dynamics to Illuminate a Strategic Roadmap for Radiation-Based Material Innovation

As electron beam and gamma radiation methods mature, their capacity to deliver precision-engineered material properties and robust sterilization outcomes becomes an indispensable asset for businesses seeking to innovate. The convergence of enhanced accelerator designs, digital control systems, and sustainability considerations has charted a trajectory toward increasingly versatile and efficient processing solutions.

Navigating the complexities introduced by tariff adjustments and regional infrastructure disparities demands agile procurement strategies and localized partnerships. Simultaneously, the granular insights gleaned from application-specific segmentation and regional market drivers underscore the need for tailored approaches rather than universal implementations.

By synthesizing technology trends, regulatory developments, and competitive benchmarks, this executive summary offers a roadmap for stakeholders aiming to integrate irradiation processes into their operational ecosystems. The future promises continued refinement of dose delivery precision, expansions in hybrid irradiation modalities, and deeper collaborations across the value chain, setting the stage for a new era of material innovation.

Get Tailored Strategies and Exclusive Reports by Reaching Out to Ketan Rohom to Propel Your Radiation Processing Initiatives to the Next Level

For personalized guidance on leveraging accelerated radiation technologies to unlock new revenue streams and streamline your product development roadmap, connect directly with Ketan Rohom, Associate Director of Sales & Marketing. With deep expertise in the nuances of electron beam and gamma radiation applications, Ketan can help tailor research insights to your specific strategic objectives. Reach out now to explore exclusive access options and premium analytics that empower you to make data-driven decisions, drive innovation across your processes, and gain a competitive edge in the rapidly evolving material modification landscape.

- How big is the Material Modification With eBeam & Gamma Radiation Market?

- What is the Material Modification With eBeam & Gamma Radiation Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?