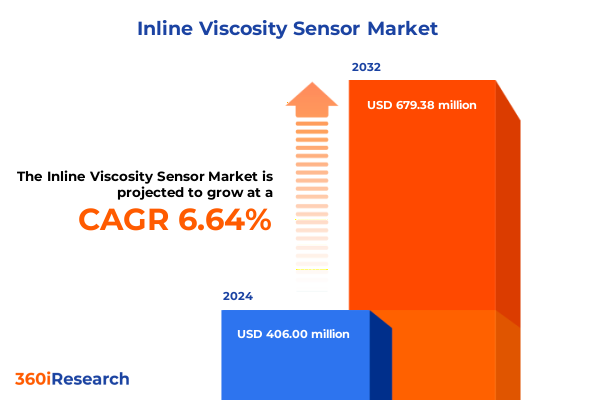

The Inline Viscosity Sensor Market size was estimated at USD 430.52 million in 2025 and expected to reach USD 456.62 million in 2026, at a CAGR of 6.73% to reach USD 679.38 million by 2032.

Discover the Crucial Role of Inline Viscosity Sensors in Modern Industrial Processes Driving Efficiency, Quality, and Innovation Across Sectors

Inline viscosity sensors are critical instruments that measure the resistance of a fluid to shear forces as it flows through a processing line. These real-time monitoring devices enable engineers to maintain precise control over fluid properties without disrupting production. By offering continuous readings of fluid viscosity, inline sensors help manufacturers ensure consistent quality, optimize energy use, and reduce waste. As a result, these sensors play a foundational role in industries where fluid behavior directly impacts product performance and safety.

In recent years, demand for real-time viscosity measurement has accelerated due to the convergence of digital transformation and process automation. Manufacturers increasingly integrate these sensors into advanced control systems to enable rapid adjustments to viscosity fluctuations. This integration not only enhances product consistency but also supports predictive maintenance strategies and lowers operational risk by identifying deviations before they escalate into equipment failures.

Across numerous sectors including chemical processing, food and beverage production, and pharmaceutical manufacturing, inline viscosity sensors deliver critical insights that underpin quality assurance frameworks. They drive streamlined workflows by eliminating the need for manual sampling and offline analysis, thereby shortening response times to process changes. Given the growing emphasis on operational efficiency and regulatory compliance, the adoption of inline viscosity monitoring has become indispensable for organizations seeking competitive advantage and sustained performance excellence.

Evolving Technologies and Market Dynamics Shaping the Future of Inline Viscosity Sensing Across Industry 4.0 and Beyond

The landscape of inline viscosity sensing has experienced profound transformation driven by breakthroughs in materials science and connectivity. Emerging piezoelectric and MEMS-based sensor designs now offer unprecedented sensitivity by detecting minute changes in resonance frequency to calculate fluid viscosity. These advanced materials enhance performance in high-stakes environments such as pharmaceutical formulation, where maintaining precise consistency is essential for efficacy and patient safety.

Simultaneously, the integration of Internet of Things technology has elevated inline viscosity sensors from standalone instruments to nodes in an interconnected industrial ecosystem. Smart sensors equipped with wireless communication capabilities feed real-time data into centralized control platforms, enabling remote monitoring and advanced analytics. This shift facilitates predictive maintenance, allowing operators to forecast equipment downtime and adjust process parameters proactively rather than reactively.

Artificial intelligence and machine learning algorithms further enrich the utility of inline viscosity data by uncovering patterns that escape traditional statistical analysis. By correlating viscosity trends with process variables, these systems empower manufacturers to fine-tune production in ways that reduce scrap, optimize throughput, and support sustainable practices. In parallel, sensor miniaturization and energy-efficient design align with global sustainability goals, enabling deployment in compact production lines and reducing the environmental footprint of critical monitoring systems.

Assessing the Far-Reaching Effects of the 2025 U.S. Tariff Regime on Inline Viscosity Sensor Supply Chains and Manufacturing Costs

The implementation of new U.S. tariffs under Section 301 has introduced complexity into the cost structures and supply chains of companies relying on imported sensor components. Increased duties on key materials such as wafers and polysilicon took effect on January 1, 2025, raising procurement costs and prompting manufacturers to reassess sourcing strategies and supplier relationships.

Beyond raw material surcharges, battery parts, semiconductors, and critical minerals relevant to sensor production have also seen escalated tariff rates, extending the impact across the value chain. Industry groups have expressed concerns that these measures, while aimed at strengthening domestic resilience, may inadvertently hinder innovation by elevating the price of advanced sensing technologies and delaying component deliveries.

In response, several companies are exploring localization of manufacturing capabilities, forging partnerships with domestic foundries, and investing in alternative material research to mitigate cost pressures. At the same time, the USTR has extended certain tariff exclusions through August 31, 2025, offering temporary relief for specific critical sectors including the medical industry. This phased approach is providing breathing space to realign global logistics without stalling development pipelines.

Despite short-term disruptions, the cumulative effect of these trade policies is expected to accelerate efforts toward supply chain diversification and foster greater collaboration between policymakers and industry stakeholders. Ultimately, organizations that adapt strategically stand to benefit from a more robust, domestically supported ecosystem for viscosity sensing technology.

Unveiling Core Segmentation Perspectives That Define Inline Viscosity Sensor Market Dynamics and Drive Tailored Solutions Across Applications

The market for inline viscosity sensors can be viewed through multiple critical lenses, each of which unveils unique opportunities. When examining product type distinctions, the microfluidic category offers rapid responses in low-volume flows, whereas rotational sensors employing cone and plate, cup and bob, or parallel plate geometries excel in high-precision laboratory and process applications. Ultrasound and vibrational sensors extend the range of deployment, enabling measurement in opaque and challenging fluid environments, from heavy slurries to delicate emulsions.

Exploring the underlying technology platforms reveals a spectrum from capacitive and Coriolis to laser Doppler and torsional resonance methods. Capacitive sensors are prized for their simplicity and cost-effectiveness, while Coriolis devices deliver mass flow–corrected viscosity data. Laser Doppler systems provide nonintrusive measurement ideal for sterile or ultra-clean processes, and torsional resonance and vibrating rod sensors combine robust construction with versatile performance across temperature and pressure extremes.

Flow regime segmentation further refines market understanding. Single-phase applications encompassing gas or liquid flows benefit from streamlined sensor integration, whereas multiphase measurement of gas–liquid, liquid–liquid, or solid–liquid suspensions demands specialized designs. Each category addresses distinct challenges, from bubble formation to particle settling, motivating customized solutions.

End-use industries range from petrochemical and specialty chemical processing to food and beverage production with beverage and dairy streams, as well as oil and gas upstream and downstream operations. Paint and coating lines require stringent viscosity control for surface finish consistency, and pharmaceutical sectors spanning API manufacturing, biotech development, and formulation leverage advanced sensors to ensure product efficacy and safety.

Finally, applications for inline viscosity sensors encompass process control through batch and continuous monitoring, quality monitoring via end-point testing and in-line quality checks, and research and development in both lab-scale experiments and pilot testing scenarios. This multilayered segmentation underscores the necessity for tailored sensor designs and service models that align precisely with performance requirements across diverse operational contexts.

This comprehensive research report categorizes the Inline Viscosity Sensor market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Technology

- Flow Type

- Application

- End-Use Industry

Exploring Key Regional Variations That Influence Demand and Innovation Patterns in the Global Inline Viscosity Sensor Market Landscape

Demand for inline viscosity sensors varies markedly by region, influenced by differing industrial priorities and regulatory environments. In the Americas, robust growth in electric vehicle manufacturing, renewable energy projects, and the expansion of chemical production facilities drives high adoption of advanced viscosity monitoring. Key players in North America prioritize integration with smart manufacturing initiatives to achieve stringent quality standards and traceability.

Across Europe, Middle East, and Africa, the push toward decarbonization and circular economy practices has accelerated investment in process analytical technologies. Automotive electrification and the modernization of petrochemical complexes foster demand for sensors that deliver precise control under wide temperature and pressure conditions. Meanwhile, regulatory frameworks related to food safety and pharmaceutical quality in Europe and the Gulf Cooperation Council reinforce continuous monitoring for critical fluid parameters.

Asia-Pacific remains the dominant region for inline viscosity sensor deployment, buoyed by large-scale chemical and semiconductor manufacturing in China, Japan, and South Korea. The uptake of Industry 4.0 from major industrial hubs integrates these sensors into fully automated lines, enhancing throughput and minimizing waste. Growth in emerging markets such as India and Southeast Asia is supported by government initiatives targeting digitalization of process industries and increased local production capacity.

Each region’s unique blend of industry focus and policy drivers shapes how companies prioritize technology investments, underscoring the importance of nuanced market approaches that respond to local requirements while leveraging global innovation trends. By aligning product roadmaps with regional dynamics, vendors can capitalize on growth pockets and reinforce their competitive positioning across diverse geographies.

This comprehensive research report examines key regions that drive the evolution of the Inline Viscosity Sensor market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Strategic Company Initiatives and Collaborations Driving Innovation and Competitive Advantage in the Inline Viscosity Sensor Industry

Leading companies in the inline viscosity sensor sector are deploying multifaceted strategies to secure competitive advantage. A number of firms have intensified research and development spending to introduce nonintrusive and miniaturized sensor models that cater to high-purity and compact process lines. These innovations not only address end-user demands for reduced maintenance but also expand applications into previously inaccessible segments such as pharmaceutical aseptic processing.

Collaborations between sensor manufacturers and control system integrators have become more prevalent, enabling seamless compatibility with distributed control systems and supervisory platforms. Such partnerships facilitate turnkey solutions, strengthening customer retention through end-to-end service offerings that encompass installation, calibration, and lifecycle management.

Mergers and acquisitions also feature prominently as established players seek to broaden their portfolios and accelerate entry into new markets. Consolidation activities have the dual effect of combining specialized expertise with global distribution networks, while fostering economies of scale in component sourcing and manufacturing.

Additionally, software and data analytics have emerged as key differentiators. Companies are embedding advanced analytics modules within their sensor platforms, offering cloud-based dashboards and predictive algorithms that convert raw viscosity readings into actionable intelligence. This shift from pure hardware to software-enabled services reflects a growing emphasis on value-added solutions and recurring revenue streams.

This comprehensive research report delivers an in-depth overview of the principal market players in the Inline Viscosity Sensor market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- A&D Company, Limited

- AMETEK.Inc.

- Anton Paar GmbH

- AVENISENSE

- Endress+Hauser AG

- FLEXIM Instruments UK Ltd.

- Galvanic Applied Sciences

- Hydramotion Ltd.

- JASCO Corporation

- KROHNE Messtechnik GmbH

- LEMIS Process

- Mettler-Toledo International Inc.

- Norcross Corporation

- Orb‑Fluid.iO Sensor + Control GmbH & Co. KG

- Petrotest Instruments GmbH & Co. KG

- Promix

- Rheonics, Inc.

- Siemens AG

- Yokogawa Electric Corporation

Actionable Strategies for Industry Leaders to Leverage Technological Advances and Navigate Supply Chain Challenges in Viscosity Measurement

Industry leaders looking to capitalize on emerging opportunities should prioritize integration of inline viscosity sensors with broader IoT and cloud platforms to unlock real-time insights and optimize process control. Investing in modular sensor architectures that support rapid configuration can reduce time to market for applications spanning chemical production to dairy processing.

To counteract tariff pressures, organizations must diversify supply chains by qualifying multiple component suppliers across different geographies. Collaborating with policymakers to secure tariff exclusions and support domestic manufacturing incentives will help maintain cost competitiveness and supply resilience.

Embracing predictive maintenance through machine learning-driven analytics will enable companies to forecast equipment wear and fluid degradation. By establishing cross-functional teams that bridge process engineering, data science, and maintenance, firms can institutionalize proactive repair schedules and minimize unplanned downtime.

Finally, strengthening customer training programs and service contracts will ensure optimal sensor performance throughout the product lifecycle. Offering comprehensive support services, from installation to remote diagnostics, not only enhances customer satisfaction but also provides ongoing revenue streams critical for long-term business sustainability.

Robust Methodological Framework Outlining Research Approaches and Validation Processes Underpinning the Inline Viscosity Sensor Market Analysis

This analysis synthesizes insights drawn from a robust combination of primary and secondary research methodologies. Secondary research encompassed a thorough review of industry publications, regulatory updates, and technology white papers to capture prevailing trends and policy impacts.

Primary research involved structured interviews with senior executives, process engineers, and procurement specialists from key end-use industries. These discussions provided qualitative perspectives on emerging requirements, adoption barriers, and technology roadmap expectations. Data triangulation across multiple sources ensured consistency and reliability of insights.

Quantitative validation was achieved through supplier questionnaires and historical shipment data analysis, cross referenced against publicly available trade and tariff records. Segmentation analysis followed a multi dimensional approach, evaluating product, technology, flow type, end-use, and application categories to build a granular understanding of market drivers.

Regional and company level insights were further validated through expert workshops, which facilitated peer review of preliminary findings. The combined methodological framework guarantees that conclusions are both data-driven and aligned with real world operational contexts, supporting informed decision making.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Inline Viscosity Sensor market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Inline Viscosity Sensor Market, by Product Type

- Inline Viscosity Sensor Market, by Technology

- Inline Viscosity Sensor Market, by Flow Type

- Inline Viscosity Sensor Market, by Application

- Inline Viscosity Sensor Market, by End-Use Industry

- Inline Viscosity Sensor Market, by Region

- Inline Viscosity Sensor Market, by Group

- Inline Viscosity Sensor Market, by Country

- United States Inline Viscosity Sensor Market

- China Inline Viscosity Sensor Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 2544 ]

Conclusive Insights Highlighting the Strategic Importance of Inline Viscosity Sensors for Operational Excellence and Future Industry Resilience

Inline viscosity sensors have emerged as essential enablers of operational excellence across a wide range of industries, from chemicals and pharmaceuticals to food and beverage and oil and gas. The convergence of advanced materials, digital connectivity, and intelligent analytics is reshaping the market, driving the development of more precise, reliable, and sustainable sensing solutions.

While U.S. tariff measures have introduced cost headwinds and supply chain complexities, they have also accelerated strategic localization initiatives and fostered closer collaboration between manufacturers, suppliers, and policymakers. Companies that adapt through diversified procurement strategies and continuous innovation will be best positioned to thrive.

Detailed segmentation of product types, technologies, flow regimes, end-use applications, and geographic markets highlights the diverse requirements shaping sensor design and service models. Tailoring solutions to these nuanced contexts is paramount for achieving performance targets and delivering measurable value to customers.

Looking ahead, the alignment of R&D investments with evolving customer needs, regulatory standards, and sustainability imperatives will determine market leaders. By leveraging actionable insights and methodological rigor, organizations can enhance process control, reduce waste, and secure lasting competitive advantage in the dynamic landscape of inline viscosity measurement.

Engage with Ketan Rohom for Exclusive Access to Comprehensive Inline Viscosity Sensor Market Research and Insights Tailored to Your Organization

For organizations seeking deep insights into the inline viscosity sensor market, connect directly with Ketan Rohom, Associate Director of Sales & Marketing. Partnering with Ketan provides personalized guidance on how best to leverage comprehensive market intelligence to inform strategic decision making. His expertise unlocks the full potential of the research, ensuring that your team can apply actionable findings to optimize processes, drive innovation, and maintain a competitive edge. To access the complete market research report tailored to your requirements, reach out to Ketan Rohom today and secure the critical data that will underpin your next phase of growth

- How big is the Inline Viscosity Sensor Market?

- What is the Inline Viscosity Sensor Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?