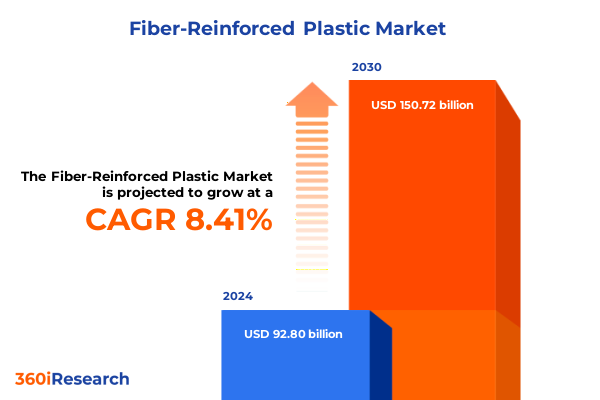

The Fiber-Reinforced Plastic Market size was estimated at USD 92.80 billion in 2024 and expected to reach USD 100.67 billion in 2025, at a CAGR 8.41% to reach USD 150.72 billion by 2030.

Introduction to the Fiber-Reinforced Plastic Market Landscape

Fiber-reinforced plastics have emerged as a pivotal material in a rapidly evolving industrial backdrop. With their combination of high strength-to-weight ratio, corrosion resistance, and design flexibility, these materials have found critical applications across diverse sectors such as aerospace, automotive, marine, and construction. In today’s market, the rapid pace of technological advancements and strategic shifts in manufacturing processes continue to redefine industry standards.

The evolution of fiber-reinforced plastics is underpinned by continuous innovations in composite materials, coupled with an increasing demand for sustainable and efficient solutions. Companies and industry leaders are steering investments into research and development, not only to meet regulatory standards but also to gain a competitive edge in performance and cost-effectiveness. The need for materials that can offer both reliability and adaptability in various environmental conditions is driving a major shift in product development strategies.

As organizations seek ways to reduce weight in transportation, enhance durability in infrastructure, and drive performance improvements in sporting goods and renewable energy applications, fiber-reinforced plastics are positioned to serve as key enablers. Their versatility also makes them an attractive solution in high-performance applications, where traditional materials may fall short. This introduction sets the stage for a deeper dive into significant market transformations, segmentation insights, regional trends, and the critical actions industry leaders must consider to stay ahead in this competitive landscape.

Transformative Shifts Redefining the Industry Landscape

Over the past decade, the fiber-reinforced plastic market has witnessed transformative shifts that are reshaping industry dynamics. Enhanced process technologies, coupled with strategic mergers and innovations in material science, are accelerating the shift towards more robust, lightweight, and multifunctional composites. These advancements are not only broadening the scope of applications but are significantly influencing how infrastructure and product lifecycle management are approached.

Manufacturers are now leveraging digital transformation, including simulation and predictive analytics, to optimize composite materials and processing techniques. This technology-driven shift allows for enhanced material design, greater precision in performance characteristics, and improved cost-efficiency. As advanced manufacturing techniques allow for more complex geometries and customization, the potential for fiber-reinforced plastics in sectors like aerospace and automotive has expanded substantially.

Environmental considerations play a crucial role in this transformation. The drive for eco-friendly manufacturing practices and recyclable materials is pushing companies to innovate beyond conventional practices. Robust recycling processes and the potential to integrate bio-resins into composite structures are contributing to more sustainable production systems. Additionally, an increase in global environmental standards has compelled manufacturers to adopt greener production techniques without compromising on performance.

Rapid innovations paired with evolving customer expectations have made this market highly dynamic. The development of novel resin formulations and specialized fibers has resulted in materials that are not only more durable but also better adapted to the specific structural demands of each application. Industry stakeholders are now more attuned to leveraging these shifts to achieve cost savings, heightened performance, and enhanced competitiveness.

These transformative changes underscore the need for a comprehensive understanding of both macro and micro-level developments in the fiber-reinforced plastic market. Integrating technological advancements with shifting environmental priorities, stakeholders today are poised to redefine traditional methods of product development and market deployment, making the current period one of unprecedented change and opportunity.

Key Segmentation Insights Across Multiple Dimensions

A detailed examination of market segmentation reveals the diverse and multifaceted nature of the fiber-reinforced plastic market. An insightful analysis starts with the resin type used in the composites. The market is distinctly categorized into thermoplastic and thermoset resins, with thermoplastics further differentiated into PEEK, polyamide, and PPS, while thermosets encompass epoxy, polyester, and vinyl ester resins. This classification importantly reflects the variations in processing techniques, end-user performance, and recyclability of the material systems.

Furthermore, segmentation by fiber type plays a crucial role in shaping the overall market outlook. With categories such as aramid, carbon, and glass fibers, each variant offers specific performance advantages. Aramid fibers are studied in sub-divisions of meta-aramid and para-aramid that cater to specialized applications where high impact resistance and durability are essential. In contrast, carbon fibers are analyzed through high modulus, intermediate modulus, and standard modulus categories. These differences enable manufacturers to balance strength, stiffness, and cost. Likewise, the contrasting specifications between E-glass and S-glass within the glass fiber segment are critical for tailored applications, ranging from everyday consumer products to high-performance systems.

Another layer of segmentation relates to application areas. The expansive application landscape includes aerospace, automotive, construction, electrical and electronics, and marine sectors. Within aerospace, the clear division between commercial and military aircraft epitomizes the demand for both lightweight materials and stringent durability standards. Similarly, the automotive sector is nuanced by its focus on chassis, exterior, and interior parts, each with distinct performance requirements. The market segments in construction, such as rebar and windows, further highlight how fiber-reinforced plastics are integrated into modern building techniques. Electrical and electronics utilize these materials for components like cable trays and switchgears, underscoring their thermal stability and resistance to harsh environments. Lastly, marine applications are bifurcated into boats and cruise ships, emphasizing the evolving performance standards in maritime environments.

In addition to raw material and application-based narratives, manufacturing process segmentation offers further insights. Diverse processing techniques such as compression molding, filament winding, injection molding, layup, and pultrusion not only influence product attributes but also dictate production efficiencies. Notably, filament winding can be subdivided into dry and wet processes, while the layup technique includes hand and spray methods, which speaks to the varied precision and scalability requirements across different production scenarios.

Finally, segmentation by end-user industry adds yet another layer of nuance. The end-user sectors include renewable energy, sporting goods, and transportation. Even within these broader categories, further sub-segmentation is evident—for example, renewable energy split into solar and wind, sporting goods into bicycles and golf clubs, and the transportation sector into automotive and rail, each demanding different performance standards and cost considerations. In essence, the integrated view of segmentation provides stakeholders with a comprehensive perspective that helps in tailoring approaches, optimizing manufacturing processes, and targeting specific verticals efficiently.

- Resin Type

- Fiber Type

- Application

- Manufacturing Process

- End User Industry

Key Regional Trends Driving Market Evolution

The global market landscape for fiber-reinforced plastics is deeply influenced by regional trends. In the Americas, technological advancements and an increased focus on sustainable manufacturing are pushing industry standards to new heights, while regulatory frameworks foster innovation and competitive advantage. The diversity of industries operating in North and South America has created a robust demand for lightweight and durable composite materials.

In the Europe, Middle East & Africa region, stringent environmental policies along with a strong manufacturing base drive the adoption of advanced composite materials. Manufacturers in these regions are increasingly investing in next-generation composites to meet energy, performance, and sustainability targets. Furthermore, evident collaboration between research institutions and industry players has spurred innovation and accelerated the transition towards high-performance, eco-friendly products.

Asia-Pacific remains at the forefront of growth dynamics, driven by rapid urbanization, a surge in industrial activities, and a strong push towards technological integration. With economies in this region prioritizing innovation and cost efficiency, the market for fiber-reinforced plastics is witnessing significant expansion. The concentrated focus on industrial modernization and increased global trade underpins the surge in demand for versatile and high-performance composite materials.

- Americas

- Asia-Pacific

- Europe, Middle East & Africa

Key Insights from Leading Industry Players

The competitive arena within the fiber-reinforced plastics market is distinguished by a plethora of well-established players and emerging innovators. Industry leaders such as Action Composite Technology Limited, Alformet B.V., and CompLam Material Co., Ltd. have set benchmarks with advanced processes and superior material quality. Crosby Composites Ltd. and DowAksa Ileri Kompozit Malzemeleri San. Ltd. Şti. continue to push technological boundaries, while firms like Gen 2 Carbon Limited and Hyosung Group maintain dominant market positions through consistent product enhancement and customer-centric strategies.

Jiangsu Hengshen Co., Ltd. and Mitsubishi Chemical Group Corporation are known for their prowess in combining high-performance technologies with sustainable manufacturing practices. The presence of Nippon Steel Corporation and Pioneer Carbon India reflects the market’s evolution towards integrated production systems, whereas Plasan Sasa Ltd. and Röchling SE & Co. KG are recognized for their expansive range of applications in critical engineering sectors. The strategic innovations at SGL Carbon SE, Sika AG, and Solvay S.A. underscore their commitment to delivering advanced composite solutions that cater to ever-evolving market needs and standards.

- Action Composite Technology Limited

- Alformet B.V.

- CompLam Material Co., Ltd.

- Crosby Composites Ltd.

- DowAksa Ileri Kompozit Malzemeleri San. Ltd. Şti.

- Gen 2 Carbon Limited

- Hyosung Group

- Jiangsu Hengshen Co., Ltd.

- Mitsubishi Chemical Group Corporation

- Nippon Steel Corporation

- Pioneer Carbon India

- Plasan Sasa Ltd.

- Röchling SE & Co. KG

- SGL Carbon SE

- Sika AG

- Solvay S.A.

Actionable Recommendations for Industry Leaders

Industry leaders must adopt a proactive approach by continuously investing in research and development to unlock innovative composite formulations and processing techniques. It is essential that companies integrate cutting-edge simulation technologies and predictive maintenance practices to optimize production efficiency and product performance. Collaboration with academic institutions and research organizations enhances access to novel findings, ensuring that companies remain at the forefront of material innovation.

A strategic focus on sustainability should guide decision-making processes. Leaders are encouraged to explore eco-friendly manufacturing technologies and advanced recycling methodologies that reduce environmental impact while sustaining product integrity. By integrating renewable raw materials and environmentally conscious manufacturing practices, organizations can meet the rising global demand for sustainable products without compromising on quality.

Furthermore, adopting a customer-centric business model that emphasizes customized solutions tailored to specific industry requirements can provide a competitive edge. This involves a thorough understanding of the unique demands across various end-user sectors such as aerospace, automotive, and marine. Proactively addressing changes in regulatory standards and market preferences will allow companies to streamline their production processes and optimize supply chain management.

It is also beneficial for companies to form strategic alliances and partnerships. Collaborations across the value chain—from raw material suppliers to technology innovators—can spur advancements and accelerate time-to-market for new products. A balanced approach that combines short-term tactical decisions with long-term strategic planning will empower companies to navigate industry disruptions with agility.

Lastly, continuous market intelligence gathering is crucial. Industry leaders should actively monitor regional market dynamics, technological trends, and competitive movements to refine their strategies and investments. Embracing digital transformation initiatives will further enhance operational resilience and readiness to capitalize on emerging opportunities in the fast-evolving landscape of fiber-reinforced plastics.

Ask ResearchAI anything

World's First Innovative Al for Market Research

Conclusion: Navigating the Future Landscape with Strategic Insight

In summary, the fiber-reinforced plastics market is characterized by dynamic innovation, expansive segmentation, and geographically diversified growth. This comprehensive analysis highlights how rapid advancements in material science and manufacturing processes are reshaping traditional industry paradigms. The insights presented underscore the importance of a detailed understanding of resin types, fiber types, applications, manufacturing processes, and end-user industries. Such an understanding is pivotal to harnessing market opportunities and fostering sustained competitive advantage.

The sector’s evolution is driven by transformative shifts that include technological integration, sustainability imperatives, and heightened regulatory frameworks. Stakeholders who leverage these insights and invest in long-term strategic planning will find themselves well positioned to meet the emerging demands of a globalized market. Through strategic collaborations, advanced digital tools, and a relentless focus on innovation, companies in this space can not only address current challenges but also anticipate future market trends.

The growing emphasis on eco-friendly practices along with the rising demand for high-performance composites marks a new chapter in the history of fiber-reinforced plastics. In the long run, those who adapt to these changes with agility and foresight are likely to drive market leadership on a global scale. A keen eye on research, combined with responsive production techniques, will be the hallmark of success in this competitive and rapidly evolving industry.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Fiber-Reinforced Plastic Market, by Resin Type

- Fiber-Reinforced Plastic Market, by Fiber Type

- Fiber-Reinforced Plastic Market, by Application

- Fiber-Reinforced Plastic Market, by Manufacturing Process

- Fiber-Reinforced Plastic Market, by End User Industry

- Americas Fiber-Reinforced Plastic Market

- Asia-Pacific Fiber-Reinforced Plastic Market

- Europe, Middle East & Africa Fiber-Reinforced Plastic Market

- Competitive Landscape

- List of Figures [Total: 27]

- List of Tables [Total: 904 ]

Call-To-Action: Engage with Ketan Rohom to Access In-Depth Market Data

For executives and decision-makers looking to gain a robust understanding of the fiber-reinforced plastics market dynamics, this report offers a data-rich analysis, forward-looking insights, and strategic recommendations. Unlock the potential of in-depth market research, comprehensively covering key segmentation, regional trends, and competitive landscapes. With actionable intelligence that spans material innovation and global market trends, the robust analysis in this report equips industry leaders with the necessary tools to craft effective strategies and enhance operational performance.

Connect with Ketan Rohom, Associate Director of Sales & Marketing, to secure your copy of the market research report. His expertise and dedication to industry excellence ensure you receive comprehensive insights to support your strategic decisions. Take the next step towards market leadership by reaching out today for a report that can reshape your approach to investment and innovation within the fiber-reinforced plastics market.

- How big is the Fiber-Reinforced Plastic Market?

- What is the Fiber-Reinforced Plastic Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?