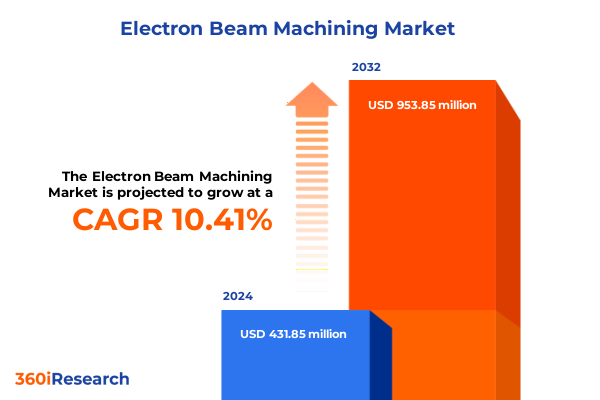

The Electron Beam Machining Market size was estimated at USD 471.79 million in 2025 and expected to reach USD 521.32 million in 2026, at a CAGR of 10.57% to reach USD 953.85 million by 2032.

Unveiling the Core Principles and Strategic Importance of Electron Beam Machining within Today’s High-Precision Manufacturing Landscape

Electron beam machining (EBM) harnesses a focused stream of high-velocity electrons to remove material through localized heating, melting, or vaporization under vacuum conditions. The process begins when electrons, accelerated by a high voltage difference between a cathode and an anode, are concentrated into a narrow beam using electromagnetic lenses. Upon impacting the workpiece surface, most of the kinetic energy converts to thermal energy, enabling micro-scale drilling, cutting, and surface modification with exceptional dimensional accuracy and minimal heat-affected zones.

Traditionally employed for hard, heat-resistant materials such as titanium alloys, ceramics, and superalloys, EBM is uniquely suited to applications requiring intricate geometries and fine edge fidelity. Its non-contact nature eliminates tool wear, while the pulsed beam operation-where pulse durations can range from 50 microseconds to 15 milliseconds-allows precise control over energy per pulse. As a result, manufacturers can achieve narrow kerf widths and superior surface finishes that are difficult to replicate with other thermal cutting processes. The need for vacuum operation limits workpiece size but underscores the process’s specialized role in high-precision sectors.

Rapid Technological Convergence and Innovation Dynamics Redefining the Electron Beam Machining Industry at the Dawn of a New Manufacturing Era

The electron beam machining industry is undergoing a profound transformation driven by the convergence of digital technologies, advanced materials, and hybrid manufacturing paradigms. Smart factories now integrate EBM systems with real-time process monitoring and closed-loop feedback, enabling dynamic adjustment of beam parameters through machine learning algorithms. These AI-driven optimizations minimize trial-and-error iterations, accelerating time-to-market for complex components in aerospace and defense sectors.

Simultaneously, hybrid platforms that couple electron beam machining with additive processes are emerging as game-changers. Manufacturers can now perform near-net-shape fabrication using additive techniques before leveraging EBM for precision finishing in a single setup. This seamless integration reduces handling errors and streamlines production workflows. Moreover, breakthroughs in electrostatic lens design and beam shaping hardware have elevated edge fidelity, enabling ultra-fine feature creation on advanced composites and ceramic matrices.

Sustainability and connectivity considerations further reinforce these shifts. EBM’s low waste generation and efficient energy utilization align with corporate decarbonization goals, while its compatibility with digital twin modeling empowers virtual validation of process parameters. As a result, electron beam machining is no longer viewed as a niche tool but as a central enabler of agile, data-driven manufacturing strategies in the era of Industry 4.0.

Assessing the Cumulative Impact of Escalating U.S. Tariff Measures through 2025 on Electron Beam Machining Supply Chains and Manufacturing Competitiveness

Throughout 2025, U.S. trade policy has introduced significant tariff measures that reverberate through electron beam machining supply chains and procurement strategies. Effective January 1, the Office of the U.S. Trade Representative applied additional Section 301 duties-raising rates on key inputs such as tungsten products by 25% and solar wafers and polysilicon by 50%-as part of a statutory review aimed at countering unfair Chinese trade practices. These measures build upon existing Trump-era tariffs, substantially increasing landed costs for equipment and consumables often sourced from global suppliers.

Beyond Section 301, reciprocal tariffs implemented in April 2025 introduced a baseline of 10% on virtually all imports, layering on top of existing duties to create total tariff rates that, in some cases, exceed 170% on China-origin goods. This escalation has disrupted established sourcing channels for precision components and machine tools, driving U.S. manufacturers to reconsider inventory strategies, reorder lead times, and supplier diversification efforts. Industry associations warn that rising duties on industrial machinery risk slowing reshoring initiatives by inflating capital expenditure requirements for new EBM installations.

In response, the USTR launched a temporary exclusion process through March 31, 2025, allowing importers to petition for relief on specified machinery subheadings. While granted exclusions provide short-term mitigation, their limited duration underscores the need for strategic planning. Companies must weigh the benefits of securing exclusions against the operational risks of deferred equipment deployment, all while navigating an evolving policy environment that could see further adjustments in the months ahead.

Dissecting Electron Beam Machining Market Dynamics through Multifaceted Application-Driven, Process-Centric, Material-Based, Equipment-Specific, and Energy-Level Segmentation Insights

Insight into electron beam machining market dynamics emerges most clearly when examining the industry through the lenses of five distinct segmentation strategies. A segmentation based on application reveals that aerospace manufacturers demand EBM for critical engine components and precision fuel injection nozzles, while the automotive sector prioritizes its use for micro-drilling and cutting of lightweight alloys. In the electronics industry, the technique’s ability to craft micron-scale features supports the fabrication of high-frequency circuit elements. Energy-focused applications leverage EBM to machine robust components for turbines, and the medical field relies on its ultrafine accuracy to produce surgical instruments and implants.

Process type segmentation highlights how cutting, drilling, surface treatment, and welding each benefit from EBM’s precise energy delivery. Cutting operations achieve narrow kerf widths on hard materials, whereas drilling exploits high energy density to form deep, high-aspect-ratio holes. Surface treatment segments apply the beam for deburring, cleaning, or surface hardening, and welding variants capitalize on concentrated heat inputs to join dissimilar metals without introducing contaminants.

Material-based insights show that ceramics and advanced composites pose significant challenges for conventional tools, yet they are effectively machined by high-velocity electron streams. Among metals, ferrous alloys like steel benefit from rapid edge formation, while non-ferrous materials-ranging from titanium to aluminum alloys-witness minimal heat-affected zones and superior surface quality. Equipment segmentation distinguishes portable units, valued for on-site repairs and maintenance, from stationary systems that anchor high-volume production lines. Finally, energy-level segmentation clarifies that low-energy setups excel in micromachining delicate features, medium-energy systems strike a balance for general-purpose tasks, and high-energy platforms tackle thick, refractory materials with speed and efficiency.

This comprehensive research report categorizes the Electron Beam Machining market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Process Type

- Material

- Machine Type

- Energy Level

- Application

Mapping Regional Electron Beam Machining Adoption Trends Amid Varying Industrial Growth, Regulatory Frameworks, and Technological Ecosystems across Americas, EMEA, and Asia-Pacific Markets

Regional adoption of electron beam machining reflects the unique industrial strengths and policy environments across the Americas, Europe, Middle East & Africa, and Asia-Pacific. In the Americas, strong aerospace and defense sectors in the United States and Canada drive demand for high-precision machining capabilities. These markets emphasize advanced research collaborations and government-supported programs to integrate EBM into mission-critical manufacturing applications.

Across Europe, the Middle East, and Africa, regulatory frameworks focusing on sustainability and energy efficiency have accelerated the adoption of low-waste processes like EBM. European automotive and medical device producers leverage the technology’s precision and environmental advantages, while emerging manufacturing hubs in the Middle East invest in advanced machining for power generation components.

In the Asia-Pacific region, rapid expansion of electronics and semiconductor manufacturing in countries such as China, South Korea, and Japan fuels demand for EBM systems capable of micron-level feature creation. Government incentives supporting high-tech industries further bolster investments, and regional machine builders increasingly offer localized service and support, enhancing appeal for domestic producers seeking minimal downtime and turnkey solutions.

This comprehensive research report examines key regions that drive the evolution of the Electron Beam Machining market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling the Global Electron Beam Machining Vanguard: Insights into Innovation, Market Presence, and Strategic Positioning of Leading Industry Players

The competitive landscape of electron beam machining is shaped by a mix of legacy equipment manufacturers, specialized system integrators, and service-oriented providers. Global Beam Technologies in Germany leads the charge with a diversified portfolio spanning welding, drilling, and surface treatment systems, underpinned by its Steigerwald Strahltechnik and PTR Strahltechnik subsidiaries. Mitsubishi Electric extends its industrial automation expertise to EBM through high-voltage, high-precision solutions tailored for heavy industries, whereas Pro-Beam’s flexible machine designs, offering power outputs from 3 kW to 15 kW, cater to both bespoke and mid-scale manufacturing needs.

Cambridge Vacuum Engineering and Bodycote, both based in the U.K., combine robust vacuum technology with advanced beam control to serve aerospace and electronics customers seeking submicron accuracy. In North America, Sciaky has carved a niche with its proprietary IRISS closed-loop control system for additive and welding applications, enabling real-time adaptive adjustments that ensure consistent geometry and mechanical properties.

Emerging players such as Evobeam and Beijing Zhong Ke Electric Co. contribute regional diversity, focusing on cost-competitive models for ceramic and composite machining. Sodick in Japan and FOCUS GmbH in Germany supplement the market with specialized lithography and nanofabrication variants, while state-owned AVIC in China integrates EBM into a broader defense and aerospace manufacturing ecosystem.

This comprehensive research report delivers an in-depth overview of the principal market players in the Electron Beam Machining market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Arcam AB

- Beijing Zhong Ke Electric Co., Ltd.

- Bodycote plc

- Comet Holding AG

- Electron Beam Technology International, Inc.

- Electron Beam Welding Ltd

- Freemelt AB

- ProBeam GmbH

- PVA TePla AG

- Retech Systems LLC

- Sciaky, Inc.

- Sodick Co., Ltd.

- TRUMPF GmbH + Co. KG

Strategic Recommendations to Propel Electron Beam Machining Leadership through Digital Integration, Supply Chain Resilience, and Collaborative Innovation Pathways

Industry leaders seeking to harness the full potential of electron beam machining should pursue a strategic roadmap that emphasizes digital integration, supply chain resilience, and collaborative innovation. First, embedding EBM systems within a digital ecosystem-leveraging digital twin simulations, real-time analytics, and AI-driven parameter tuning-can significantly enhance process repeatability and reduce development cycles. Organizations should invest in interoperable software platforms that facilitate data exchange across design, simulation, and production stages.

Second, companies must proactively address tariff-induced supply disruptions by diversifying their supplier base, qualifying alternative sources for critical components, and engaging early in exclusion request processes when applicable. Developing strategic partnerships with regional equipment providers can mitigate lead-time risks while ensuring ongoing technical support.

Finally, fostering cross-industry collaborations can unlock novel applications and shared cost structures. Joint R&D initiatives with materials scientists, automation specialists, and end users can drive the creation of hybrid machining platforms, new beam shaping techniques, and eco-optimized chamber designs. By aligning these efforts with sustainability goals-such as energy-efficient vacuum systems and low-waste workflows-leaders will position themselves at the forefront of next-generation precision manufacturing.

Comprehensive Research Methodology Leveraging Primary Expert Interviews, Rigorous Secondary Analysis, and Cross-Validated Data Triangulation for Electron Beam Machining Insights

This report’s findings are anchored in a comprehensive research methodology combining both primary and secondary data sources. Primary research entailed in-depth interviews with subject matter experts, including equipment OEM executives, process engineers, and R&D directors, to capture first-hand insights into emerging applications, technology roadmaps, and capital expenditure priorities.

Secondary research involved systematic analysis of publicly available regulatory filings, patent databases, academic journals, trade association publications, and reputable news outlets. Data triangulation techniques were applied to validate qualitative insights against quantitative evidence, ensuring robust cross-verification and reducing the risk of single-source bias.

Throughout the research lifecycle, an iterative review process was maintained, wherein preliminary findings were shared with industry advisors for feedback. This approach facilitated refinement of key themes, validation of segmentation frameworks, and confirmation of regional trends, resulting in a nuanced and actionable industry assessment.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Electron Beam Machining market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Electron Beam Machining Market, by Process Type

- Electron Beam Machining Market, by Material

- Electron Beam Machining Market, by Machine Type

- Electron Beam Machining Market, by Energy Level

- Electron Beam Machining Market, by Application

- Electron Beam Machining Market, by Region

- Electron Beam Machining Market, by Group

- Electron Beam Machining Market, by Country

- United States Electron Beam Machining Market

- China Electron Beam Machining Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1113 ]

Concluding Synthesis of Key Electron Beam Machining Industry Trends, Challenges, and Opportunities Shaping Its Next-Generation Manufacturing Impact

Electron beam machining stands at a pivotal juncture, driven by technological innovation, evolving policy dynamics, and global competitive pressures. As digitalization and hybrid manufacturing approaches converge, EBM systems will transition from specialized niche tools to integral components of smart production environments. The industry’s ability to adapt to shifting tariff landscapes and regulatory frameworks will determine the pace of equipment adoption and supply chain resilience.

Segmentation analysis underscores that success will hinge on offering tailored solutions across diverse applications, from aerospace-grade alloys to biomedical implants, while addressing process-specific requirements in cutting, drilling, surface treatment, and welding. Regional insights reveal that strategic investments in local partnerships and sustainable operations will be critical to capitalizing on growth pockets in the Americas, EMEA, and Asia-Pacific.

Leading organizations that embrace digital twin modeling, proactive tariff mitigation, and collaborative R&D initiatives will unlock new performance thresholds and operational efficiencies. In doing so, they will shape the next phase of electron beam machining’s evolution, ensuring it fulfills its promise as a cornerstone of high-precision, low-waste manufacturing ecosystems.

Take the Next Step Today by Engaging with Ketan Rohom to Access the Definitive Electron Beam Machining Market Intelligence Report Tailored for Decision Makers

Ready to transform your strategic approach to precision manufacturing? Reach out directly to Ketan Rohom, Associate Director, Sales & Marketing, to unlock unparalleled insights into the electron beam machining landscape. Our in-depth report delivers comprehensive analysis of technological advances, supply chain dynamics, tariff impacts, and competitive positioning, empowering your organization with the intelligence needed to outpace rivals and capitalize on emerging opportunities. Connect with Ketan today to discuss tailored packages, customization options, and exclusive data sets that align with your strategic priorities. Make confident, data-driven decisions that drive growth, optimize operations, and solidify your leadership in the next era of high-precision machining.

- How big is the Electron Beam Machining Market?

- What is the Electron Beam Machining Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?