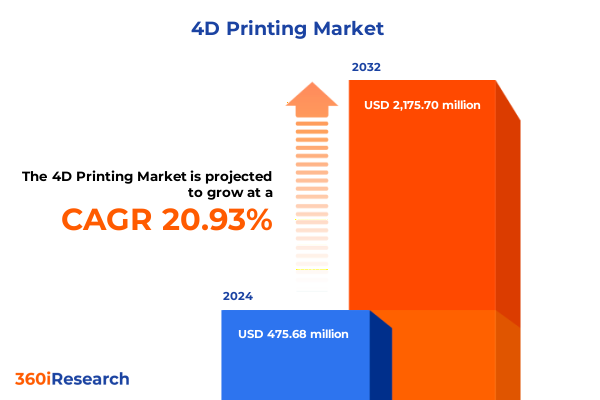

The 4D Printing Market size was estimated at USD 574.51 million in 2025 and expected to reach USD 695.69 million in 2026, at a CAGR of 20.95% to reach USD 2,175.70 million by 2032.

Comprehensive Overview of Four-Dimensional Printing Innovations Unveiling How Shape-Shifting Smart Materials Are Pioneering Adaptive Manufacturing

The evolution of additive manufacturing has entered a new era with the emergence of four-dimensional printing, a process that integrates time as an active design parameter by leveraging shape-responsive materials. Unlike traditional three-dimensional printing, which focuses on static geometries and material deposition, four-dimensional printing involves the programming of material behaviors that unfold post-production, enabling components to change form or function when exposed to external stimuli such as temperature, moisture, or pH changes. This convergence of advanced materials science and precise fabrication techniques sets the stage for constructing dynamic structures capable of self-assembly, self-repair, and reconfiguration. In this context, the introduction of programmable polymers and composites underpins a new manufacturing paradigm where adaptability and responsiveness are engineered into the very fabric of the product.

As industries strive to meet ever-more stringently defined performance criteria, four-dimensional printing presents an opportunity to revolutionize product design, operational efficiency, and lifecycle management. Early applications in fields ranging from biomedical devices to aerospace components demonstrate the capacity for time-dependent transformations to reduce inventory complexity, facilitate on-demand customization, and improve sustainability through reduced material waste. With ongoing breakthroughs in smart materials and digital design platforms, four-dimensional printing is poised to transition from a laboratory curiosity to an indispensable toolkit for manufacturers seeking to differentiate through innovation and adaptive functionality.

Breakthrough Technological Advances and Material Innovations Driving Four-Dimensional Printing Toward New Horizons in Biomedicine Mobility and Structural Design

Recent advances in material engineering and digital manufacturing platforms have accelerated the progression of four-dimensional printing from conceptual research to applied innovation. Tailored shape memory polymers and composite formulations are now being optimized for predictable, repeatable transformations, enabling applications such as deployable aerospace structures that compact for transport and expand in orbit. Parallel developments in artificial intelligence–driven design software further streamline the iteration process, allowing engineers to simulate multi-stage behavioral responses before physical prototyping. Moreover, the integration of real-time sensing capabilities and feedback loops into printed constructs is unlocking pathways toward autonomous adaptation, as evidenced by prototypes that adjust stiffness or porosity to changing environmental loads.

Simultaneously, industry consortia and academic collaborations are fostering standardization frameworks and best practices to address challenges in repeatability, material characterization, and quality assurance. These synergistic efforts underpin a maturing ecosystem where materials suppliers, equipment manufacturers, and end users coalesce around shared platforms and certification protocols. As a result, transformative shifts are underway: manufacturing supply chains are evolving to incorporate on-site adaptive production nodes, and design-for-every-condition philosophies are replacing static value chains. The broadening of use cases into sectors such as consumer goods and construction is a testament to the disruptive potential of autonomous, time-responsive manufacturing technologies.

Analysis of the Aggregate Effects of 2025 United States Tariff Policies on Materials Procurement Supply Chain Stability and Cost Structures

Throughout 2025, United States tariff adjustments have markedly influenced the procurement strategies and cost structures of firms engaged in four-dimensional printing. Heightened duties on imported advanced polymers and composite feedstocks have elevated baseline material expenses, prompting manufacturers to recalibrate supplier networks in favor of domestic producers or nearshoring arrangements. This strategic pivot has reshaped traditional just-in-time inventory models, as companies pursue deeper bilateral partnerships with local material innovators to secure uninterrupted access to high-performance substrates under more favorable trade conditions.

The cumulative effect of tariff-induced cost pressures extends beyond raw materials, as ancillary components and post-processing supplies also face elevated import levies. Consequently, R&D budgets are being increasingly allocated toward developing feedstock alternatives and recyclable material formulations to mitigate dependency on tariff-exposed inputs. Government incentive programs at the state and federal levels have emerged to offset these challenges, offering grants and tax credits aimed at enhancing domestic manufacturing capacity. As these policy measures coalesce with industry-driven innovation, the result is a reconfigured supply chain architecture that balances resilience, cost-efficiency, and technological agility.

In-Depth Examination of Market Segmentation Dynamics Across Offerings Material Types Printing Technologies and Diverse Application Verticals

Diverse offerings in four-dimensional printing encompass both service-centric and system-centric models, with design and post-processing services enhancing end-to-end solution capabilities alongside the deployment of desktop and industrial scale additive manufacturing equipment. Service providers deliver critical expertise in material selection, simulation of time-based transformations, and post-production conditioning to ensure that dynamic behaviors meet application-specific requirements. At the same time, equipment manufacturers continue to refine printer architectures, balancing the precision of desktop machines with the throughput and robustness of industrial platforms.

Material types represent a foundational dimension of market segmentation, spanning composite blends engineered for strength and resilience, hydrogel systems tailored for biocompatible applications, and shape memory polymers designed for programmed actuation. Each category addresses distinct performance profiles, from structural load-bearing components to stimuli-responsive biomedical scaffolds. Meanwhile, printing technologies such as fused deposition modeling, PolyJet printing, selective laser sintering, and stereolithography offer unique trade-offs between resolution, material compatibility, and production speed, enabling stakeholders to align technology selection with desired functional outcomes.

Applications of four-dimensional printing extend across aerospace components that self-deploy, automotive parts that adapt under thermal loads, and construction materials capable of morphing to optimize structural performance. Consumer products can leverage shape-changing aesthetics for personalized wearables, while the medical domain benefits from drug delivery systems that modulate release profiles, surgical tools that conform to patient-specific anatomies, and tissue engineering scaffolds that evolve to guide cell growth. Textiles conclude this spectrum, with smart fabrics exhibiting programmable texture and porosity shifts to enhance comfort and performance.

This comprehensive research report categorizes the 4D Printing market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Offering

- Material Type

- Printing Technology

- Application

Strategic Regional Perspectives Highlighting Emerging Opportunities and Infrastructure Developments in the Americas EMEA and Asia-Pacific Ecosystems

The Americas region exhibits a robust integration of four-dimensional printing into aerospace and defense supply chains, where end users prioritize lightweight, adaptive components capable of withstanding fluctuating environmental conditions. Academic research centers across North America collaborate with private firms to drive material innovation, resulting in a progressive regulatory environment that supports on-site manufacturing and rapid prototyping. South American markets are increasingly exploring hydrogel-based biomedical applications, leveraging growing investment in healthcare infrastructure and biocompatible material research.

Within Europe, the Middle East and Africa, regulatory standards and certification protocols are being harmonized to facilitate cross-border adoption of adaptive manufacturing technologies. European automotive manufacturers are piloting shape-shifting parts to improve fuel efficiency, while construction firms in the Gulf region explore programmable materials for façade systems that respond to climatic fluctuations. Meanwhile, manufacturers across Africa are beginning to adopt desktop-scale four-dimensional printers for consumer product customization and remote medical device fabrication, with an emphasis on local material sourcing to overcome import constraints.

Asia-Pacific leads in production capacity expansion, driven by government initiatives in China, Japan, and South Korea that prioritize advanced manufacturing and smart city development. Industrial conglomerates and research institutes in the region are scaling up composite and polymer feedstock production, achieving economies of scale that lower material costs. Simultaneously, medical device clusters are capitalizing on hydrogel and shape memory polymer innovations to introduce next-generation surgical tools and tissue engineering solutions into regional healthcare systems.

This comprehensive research report examines key regions that drive the evolution of the 4D Printing market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Comprehensive Company-Level Insight into Key Innovators Shaping Competitive Strategies and Collaborative Ecosystems within the Four-Dimensional Printing Industry

Leading industry participants are differentiating themselves through targeted investments in proprietary materials and platform expansions. Some have secured patents for novel shape memory polymer blends that exhibit improved thermal stability and programmable deformation profiles, establishing high barriers to entry. Others focus on modular hardware architectures, enabling seamless upgrades of printing heads and curing chambers to support a broader spectrum of material behaviors without requiring wholesale equipment replacement. Collaborative ecosystems are also taking shape, as established printer manufacturers partner with specialized material producers to co-develop integrated solutions that ensure compatibility and performance consistency.

Strategic alliances between technology firms and end users have become prevalent, facilitating real-world validation of time-responsive products and accelerating the feedback loop for iterative innovation. Investment funds targeting advanced manufacturing have increasingly directed capital toward start-ups pioneering hydrogel-based biomedical scaffolds and construction-scale adaptive materials, fueling a wave of early-stage experimentation. In parallel, acquisitions of software developers specializing in multi-physics simulation platforms highlight the critical role of virtual prototyping in predicting complex, timedependent behaviors. Collectively, these corporate maneuvers underscore a market dynamic where material intellectual property, hardware flexibility, and digital tooling converge to define competitive advantage.

This comprehensive research report delivers an in-depth overview of the principal market players in the 4D Printing market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- 3D Systems Corporation

- 4D Biomaterials Ltd.

- ARC Centre of Excellence for Electro Materials Science (ACES)

- Autodesk Inc.

- BioBots, Inc.

- CT CoreTechnologie Group

- Dassault Systèmes SE

- EnvisionTEC GmbH

- EOS GmbH Electro Optical Systems

- Hewlett Packard Company

- HP Development Company, L.P.

- Luxexcel Group BV

- Materialise NV

- MIT Self‑Assembly Lab

- Nanoscribe GmbH

- Optomec Inc.

- Organovo Holdings Inc.

- Poietis SAS

- Renishaw plc

- Sculpteo SAS

- Smart Materials 3D, Inc.

- Stratasys Ltd.

- The ExOne Company

- Voxeljet AG

- Zortrax S.A.

Actionable Strategic Recommendations for Industry Leaders to Navigate Market Complexities and Harness the Full Potential of Four-Dimensional Printing Innovations

To harness the full potential of four-dimensional printing, industry leaders should prioritize the cultivation of end-to-end ecosystems that bridge material science, digital design, and production capabilities. By investing in internal or collaborative research initiatives focused on smart material formulation, organizations can reduce exposure to tariff volatility and develop tailored feedstocks that align with unique application requirements. Concurrently, establishing strategic partnerships with software providers ensures that design workflows are optimized for accurate simulation of time-based transformations, thereby minimizing costly trial-and-error in physical prototyping.

Supply chain resilience can be fortified through dual sourcing strategies that balance domestic production of critical polymers with reliable international suppliers, supported by inventory diversification and buffer stock for tariff-exposed inputs. Performance-oriented pilot projects in targeted end markets, such as biomedical implants or deployable aerospace structures, will generate proof-of-concept data that underpin broader commercialization efforts. Finally, integrating sustainability goals by exploring recyclable or bio-based shape memory materials not only addresses environmental mandates but also opens new market segments focused on circular economy principles.

Robust Research Methodology Detailing Data Sources Validation Processes and Analytical Frameworks Underpinning the Four-Dimensional Printing Market Study

This report’s findings are grounded in a rigorous mixed-method research approach that combines primary interviews with industry stakeholders, including materials scientists, hardware engineers, and end users, to capture firsthand insights into four-dimensional printing adoption and challenges. Secondary research comprised an exhaustive review of academic journals, patent filings, regulatory guidelines, and white papers to triangulate technological advancements and policy developments across global markets. Data validation protocols involved cross-referencing multiple information sources and conducting follow-up consultations with key informants to ensure consistency and accuracy of technical parameters and market dynamics.

Analytical frameworks employed in this study include supply chain resilience modeling, competitive landscape mapping, and multi-dimensional segmentation analysis to elucidate nuanced market drivers and barriers. Scenario planning was applied to assess the implications of tariff shifts and material innovation trajectories, while sensitivity analyses evaluated potential demand fluctuations across application verticals. The integration of qualitative stakeholder feedback with quantitative trend analysis underpins a robust evidence base, enabling reliable insights that inform strategic decision-making within the evolving four-dimensional printing landscape.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our 4D Printing market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- 4D Printing Market, by Offering

- 4D Printing Market, by Material Type

- 4D Printing Market, by Printing Technology

- 4D Printing Market, by Application

- 4D Printing Market, by Region

- 4D Printing Market, by Group

- 4D Printing Market, by Country

- United States 4D Printing Market

- China 4D Printing Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1272 ]

Conclusive Insights Reinforcing the Strategic Importance and Future Outlook of Adaptive Shape-Changing Manufacturing Technologies Across Industrial Sectors

Four-dimensional printing represents a transformative leap in manufacturing capabilities, uniting dynamic materials engineering with precise digital fabrication to create products that adapt in real time to external triggers. This synthesis of smart polymers, advanced printing technologies, and cross-industry collaboration heralds a future of highly customized solutions that redefine traditional notions of product lifecycle and supply chain configuration. As material portfolios mature and standardization efforts gain traction, time-responsive manufacturing will transition from niche pilot projects to mainstream implementation across sectors ranging from healthcare and aerospace to construction and consumer goods.

Looking ahead, the strategic importance of four-dimensional printing will hinge on its ability to deliver tangible performance enhancements, operational efficiencies, and sustainability benefits. Stakeholders who capitalize on robust R&D partnerships, invest in resilient supply chains, and leverage advanced simulation tools are best positioned to lead this market’s growth trajectory. Ultimately, the integration of adaptive manufacturing paradigms will not only drive competitive advantage but also unlock new avenues for innovation that respond dynamically to changing market needs and environmental imperatives.

Engage with Ketan Rohom to Secure the Comprehensive Four-Dimensional Printing Market Report and Unlock Strategic Insights for Enhanced Decision-Making

For organizations seeking unparalleled expertise and forward-looking intelligence on four-dimensional printing, direct engagement with Ketan Rohom assures personalized guidance and streamlined access to our comprehensive market study. As Associate Director of Sales & Marketing, he offers tailored consultations to align your strategic objectives with the report’s in-depth findings and industry benchmarks.

Contacting Ketan heralds a strategic partnership focused on empowering your decision-making through robust data interpretation and actionable insights. His expertise in translating complex technological trends into pragmatic business strategies ensures that you extract maximum value from every section of the report. Reach out today to secure your copy, unlock the competitive advantages embedded within the study, and position your organization at the forefront of adaptive manufacturing innovation.

- How big is the 4D Printing Market?

- What is the 4D Printing Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?